Features

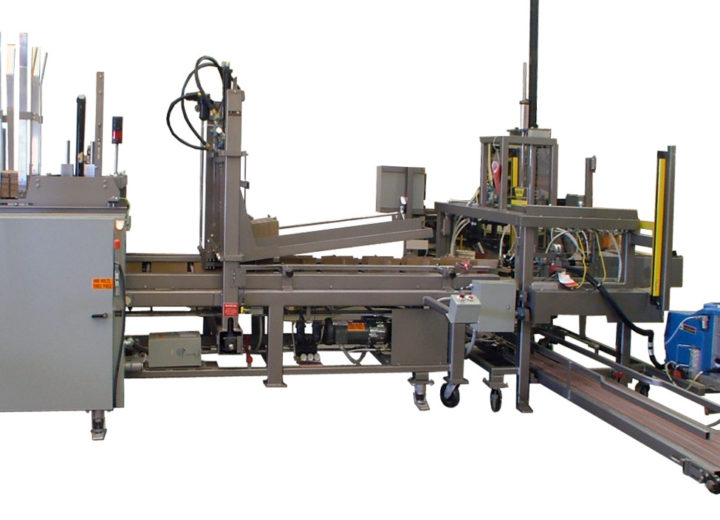

• Available in Three Models for Speeds Up to 40 Insertions Per Minute

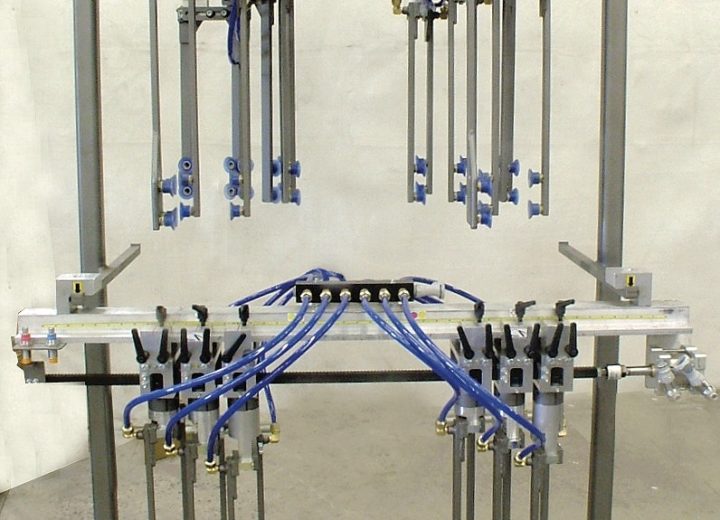

• Easy Load Magazines

• Lexan® Safety Door with Allen Bradley Anti-Intrusion Switches

• Rugged MIG Welded Rectangular Steel Frame

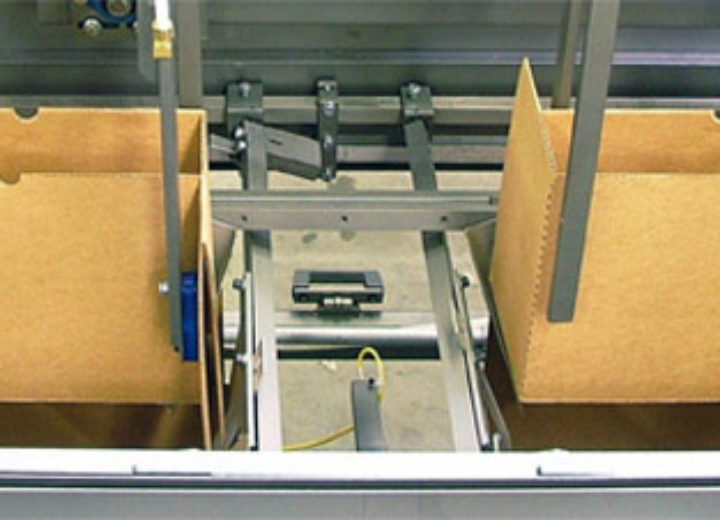

• Wide Range of Partition Sizes and Styles in Corrugated or Solid Fiber

• Handles Die-Cut Partitions Requiring Folding and Manipulations Prior to Insertion

• T-Tooling Available for Rapid Job Changes