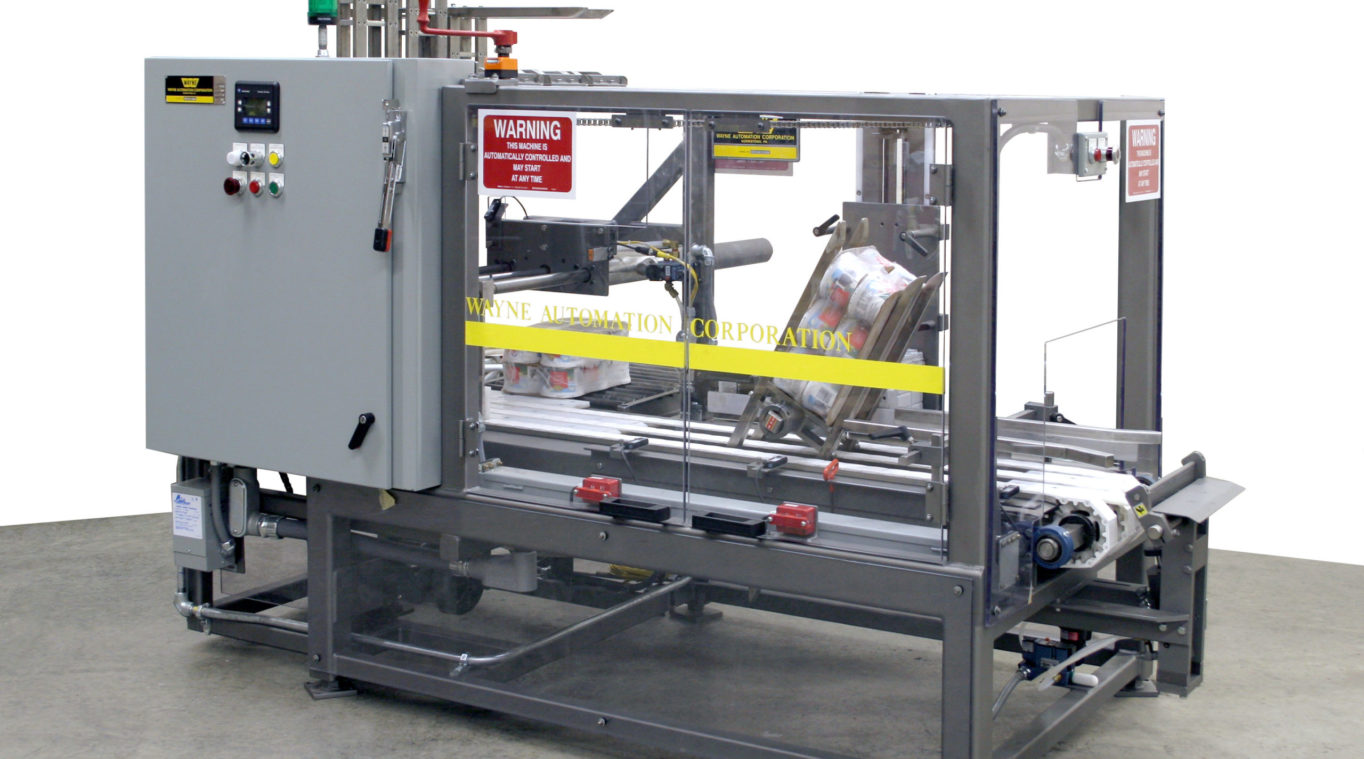

// Glass and Plastic Packaging

Popular Shoe Retailer Saves Big with Case Erector From Wayne Automation

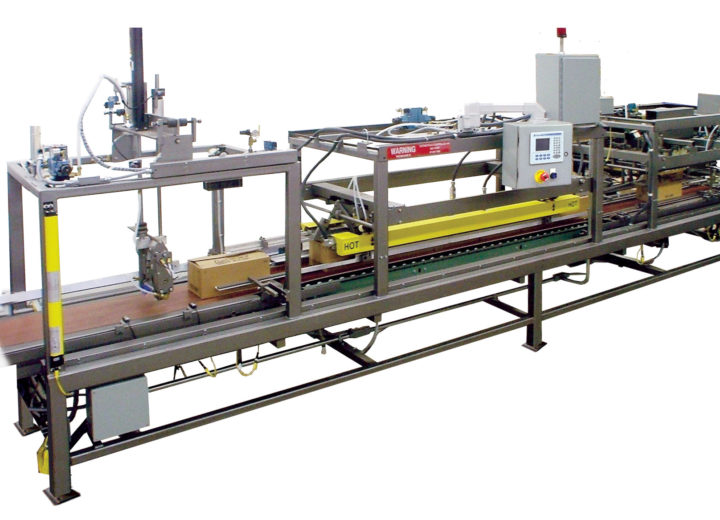

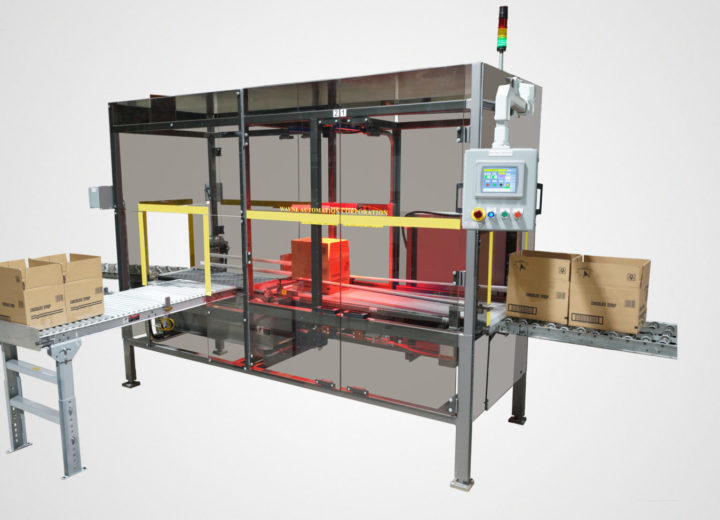

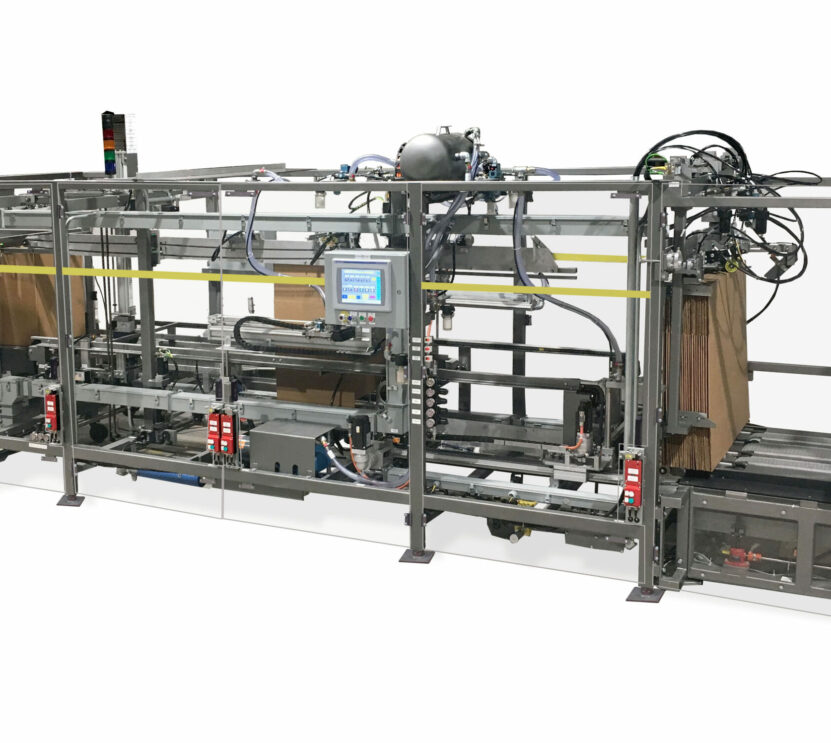

A popular shoe retailer worked with Wayne Automation to design and install a case erector machine that has so far saved them hundreds of thousands of dollars.

Challenge

Before Wayne, DTLR VILLA made all boxes by hand and became unable to keep up with demand.

Solution

Wayne Automation built and installed a case erector. DTLR VILLA saw immediate results both in space requirements for boxes, and for the labor needed to assemble those boxes.