What is Primary, Secondary & Tertiary Packaging?

Packaging is more than a protective barrier for your products: It is also a sales tool. Often, the packaging is the last thing a customer will interact with before they purchase and use your product. As a result, it’s no surprise that packaging plays a major role in attracting customers and encouraging them to buy your product.

This raises a few questions for any business that produces a product:

- What exactly do you mean by “packaging?”

- What are some secondary packaging examples?

- What is primary vs. secondary packaging?

There are technically at least three layers of standardized packaging. All three of them can collectively be known as “packaging.” However, each of them has its own distinct purpose and function. Together and separately, each layer contributes to the end goal of attracting and satisfying buyers.

For now, we’ll take a quick look at these primary, secondary, and tertiary packaging layers. Next, we’ll go through some examples of each. Finally, we’ll look at how they can work together to create an experience that will make your customers love your product before they even try it!

- Primary Packaging Examples and Components

- Secondary Packaging Examples and Components

- Tertiary Packaging Examples and Components

Primary Packaging Examples

Sometimes called “consumer packaging” or “retail packaging,” Primary Packaging is the layer that directly contacts the product.

The main purpose of primary packaging is to protect. However, this layer is also where you will find product information, imagery, ingredients, directions, etc. that inform the consumer. In some cases, like with a wine bottle, you have two forms of primary packaging: one being the bottle that holds the liquid, and then another being the label attached to the bottle for communicating the branding and contents.

Primary Packaging Components*

- Bottles

- Boxes

- Cartons

- Cans

- Jars

- Packets

- Pouches

*Note: Wayne Automation does not offer machinery for primary packaging.

This layer should have the maximum level of protection to preserve your product, and still be somewhat easy for the consumer to open. Several years ago, Consumer Reports created the “Oyster Awards” to bring attention to packages that were notably difficult to open. Although this tongue-in-cheek ceremony is no longer in effect, what it highlighted is still applicable: try to avoid frustrating your customers with your packaging.

One way you can find the balance between being overly protective and uselessly flimsy with your primary packaging is to make sure you have good secondary and tertiary packaging.

Secondary Packaging Examples

The purpose of secondary packaging is also to protect the product. However, this layer serves many other purposes. It helps to organize individual product units into groups so they can be stacked, sorted, and transported. In the beverage and food industries, products are regularly displayed while still in their secondary packaging. This is also referred to as retail-ready packaging (RRP). Secondary packaging sometimes requires a thoughtful application of a company’s branding and supporting print material.

Secondary packaging is usually constructed from corrugated cardboard into Regular Slotted Containers (RSC), Half-Slotted Containers (HSC), Full Overlap Slotted Containers (FOL), Center Special Slotted Containers (CSSC), and Partition inserts. Although building, packing, and sealing cases are the steps that occur during secondary packaging, this part of the packing process can also include sorting, labeling, and quality control checks. It is either during the secondary packaging stage or immediately after the tertiary packaging stage when boxed items are palletized and given final preparation for shipping.

Secondary Packaging Components

- Cardboard Cartons

- Chipboard Cartons

- Cardboard Boxes

- Cardboard/Plastic Crates

- Paperboard Cartons

- Trays

Tertiary Packaging Examples

If you’ve ever had the opportunity to browse around a membership warehouse store like Costco or Sam’s Club, you’ve probably seen cases of products arranged on pallets. Or, if you look up high on the shelves at those places, you’ll often see unopened cases shrink-wrapped together. This is tertiary packaging. It can also be called bulk packaging or transit packaging. It is a systemized step for grouping units created during the secondary packaging process into an even larger unit more suitable for loading, shipping, and storage.

Like primary and secondary packaging, the main purpose of tertiary packaging is to protect the products while they are transported or stored. However, unlike primary and secondary, tertiary rarely gets any branding applied. Unless shoppers go to a warehouse store, they will never see it. Tertiary packaging is primarily designed for sitting in storage facilities.

The importance of tertiary packaging is no less valuable or important than the other two. As supply chains move faster and go farther, this extra level of protection helps ensure that the work done in the primary and secondary stages is still exquisite once it’s removed from the pallet and placed on the shelf.

Tertiary Packaging Components

- Large cardboard boxes

- Pallets

- Shrink wrap plastic

How Wayne Can Help Automate Your Packaging Process

Now that you’ve seen the differences and benefits of primary, secondary, and tertiary packaging, consider how you can integrate these three layers into your production and end-of-line processes. Ultimately, your goal as a business is to create and maintain a good quality product that your customers love. You need a dependable process (and partner!) to help ensure your product stays looking sharp and alluring as it travels from your shop to the store shelf.

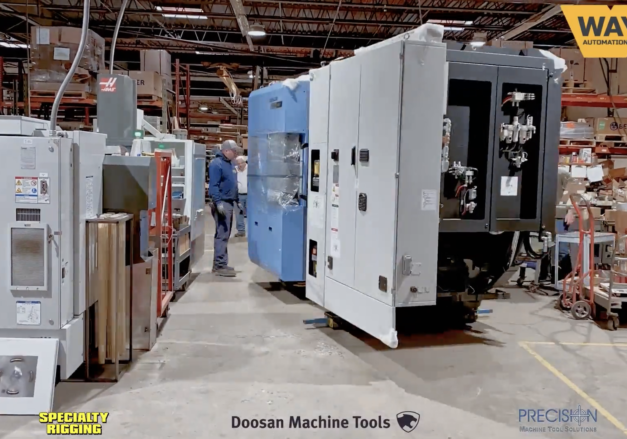

Wayne Automation has been building advanced, quality packaging machinery since 1976. Our best-in-class machines include case erectors, partition inserters, case sealers and many other innovative packaging products. Whether you know you’re ready to move into automation, or if you’re still thinking about it, we will gladly take the time to answer your questions, arrange a plant tour, or set up a product demonstration so you can make the right decision for your company.

Contact us today and talk with one of our experts.