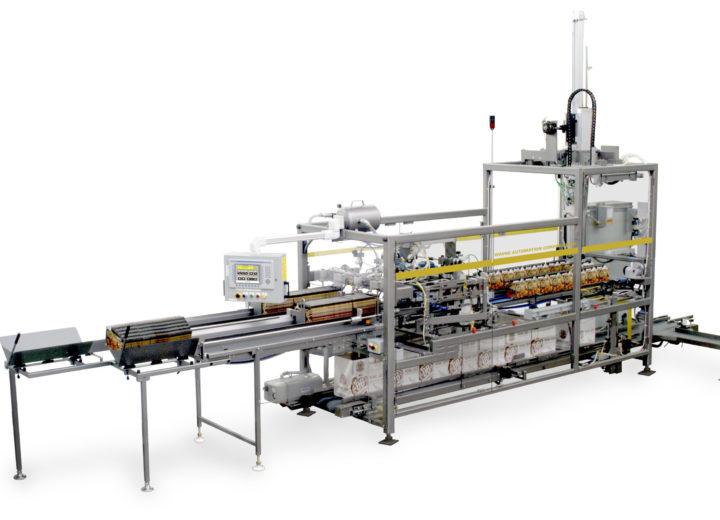

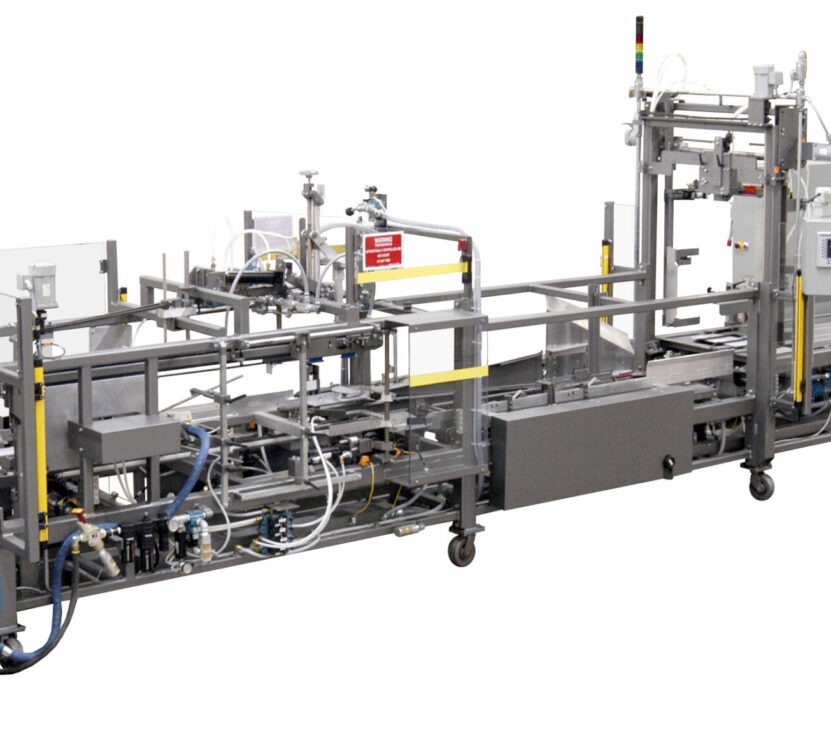

Features

• Speeds to 25cpm

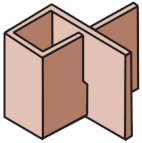

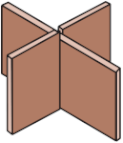

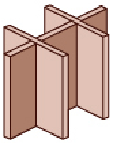

• Inserts One Partition Per Cycle

• Easy Load Magazines

• Lexan® Safety Doors with Allen Bradley Anti-Intrusion Switches

• Rugged MIG Welded Rectangular Steel Frame

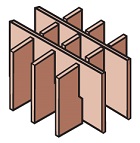

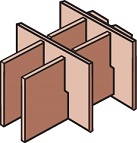

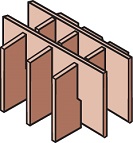

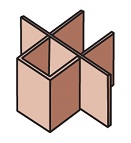

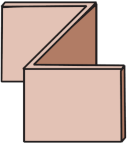

• Wide Range of Partition Sizes and Styles in Corrugated or Solid Fiber

• T-Tooling Available for Rapid Job Changes