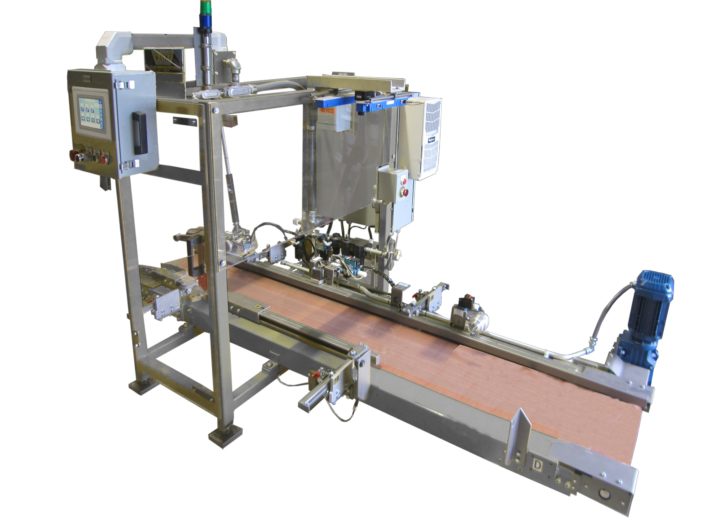

If your business is looking for a case or box sealer built to thrive in a 24/7 production environment, providing reliably excellent results, Wayne Automation has the best case sealer for you.

Our line of case sealers provide consistent performance across a range of speeds, regardless of the condition of a case’s major or minor flaps. Their compression rollers set the tape or adhesive joint, ensuring high quality results every time.

If you need to seal tall or top-heavy cases, our sealers’ side-guide stabilizing rollers will keep the package under control even at high speeds.

You’ll have peace of mind knowing you don’t have to worry about upstream line pressure adversely affecting your case sealers’ performance.