Industrial Tool Company Sees Increased Reliability & Versatility With Wayne’s Tray Formers

An industrial tool and accessory manufacturer worked with Wayne Automation to replace the existing tray formers they had from a competitor with automatic tray formers from Wayne Automation.

An industrial tool and accessory manufacturer worked with Wayne Automation to replace the existing tray formers they had from a competitor with automatic tray formers from Wayne Automation.

Their motivation in switching machinery was that they worked with such a large variety of box sizes. The company was previously running multiple machines to form the trays. Now, while the company still runs multiple machines due to their demand, each machine can handle a variety of tray sizes.

Here’s how this industrial tool and accessory company benefited from switching their existing tray former machines to Wayne Automation products.

The Problem: Inconsistent Quality & Slow Output

Manufacturing fasteners, staples, nails, and tools such as staplers, screw guns, and nailers requires packaging trays that will protect the product while in transit to major retailers.

This tool company, which sells to clients such as Home Depot and Lowes, along with other smaller companies, required updated machinery that could handle all the box sizes their diverse range of products needed.

Before seeking updated equipment and solutions with Wayne Automation, the company utilized multiple pieces of machinery that could only handle certain box sizes, not all box sizes the company needed for its products. As a result, the manufacturer ended up having different trays assembled by different machines in a process that was not efficient, consistent, or reliable.

The Solution: Tray Formers That Can Handle All Sizes

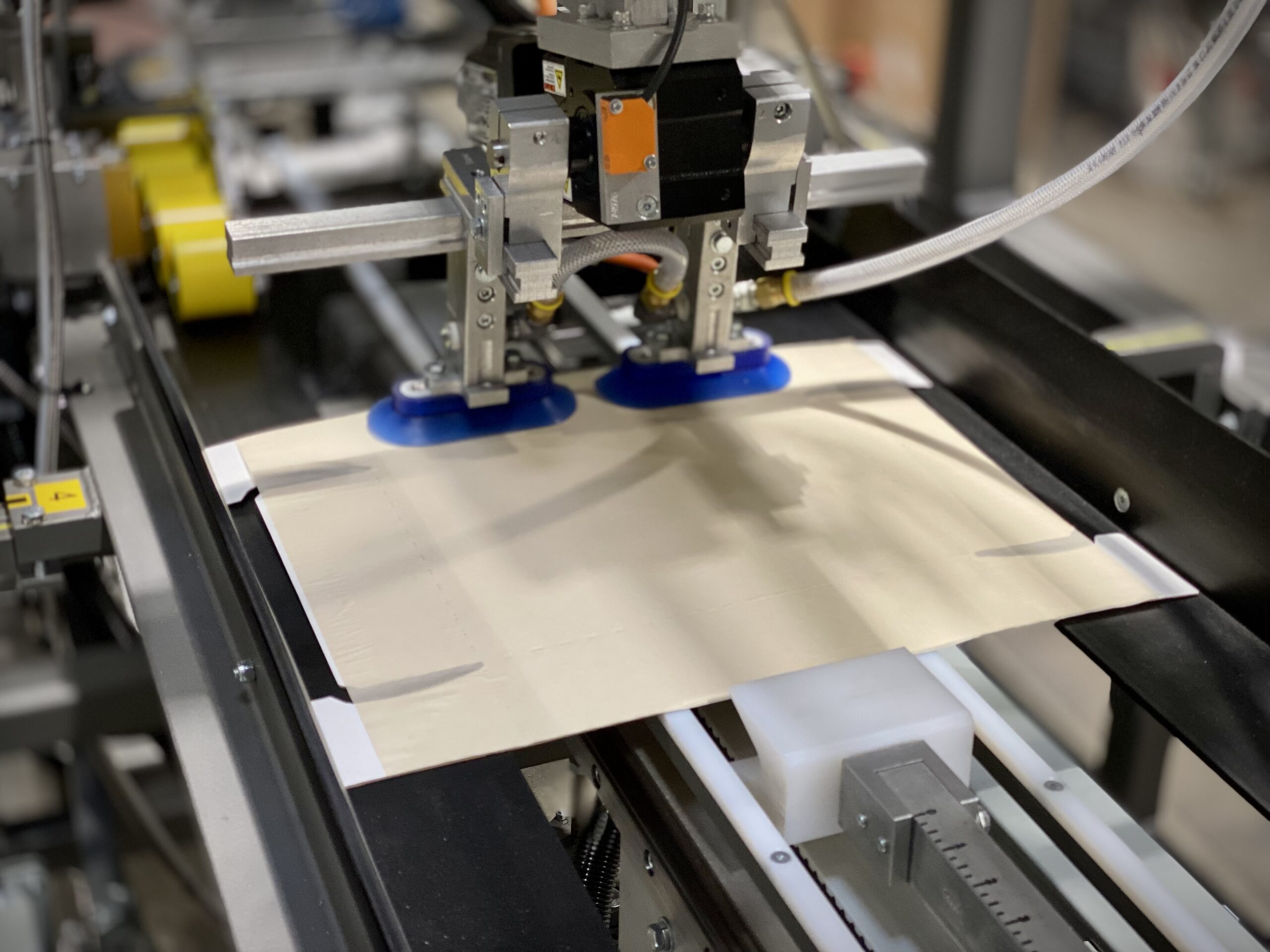

After consulting with Wayne Automation about new machinery, this tool company invested in multiple automatic tray former machines that could handle all the box sizes they needed to ship their products.

After consulting with Wayne Automation about new machinery, this tool company invested in multiple automatic tray former machines that could handle all the box sizes they needed to ship their products.

The machinery from Wayne is capable of running all the boxes on one machine. The company still has multiple machines to handle demand, but now the machinery is able to run all box sizes to increase efficiency while minimizing confusion.

Because the machinery is running such a large variety of sizes, the company needed to work with Wayne to tweak the machinery after getting set up. Now that everything is working as intended to suit this tool manufacturer’s requirements, they are running faster, and experiencing better consistency with the quality of the boxes. Time is saved, waste is reduced, and their products are shipped safely due to proper packaging size and box quality.

The company also says it’s now easier to fold the boxes because they are of higher quality–the boxes have crisper edges.

The Result: Increased Productivity & Quality

In addition to being able to assemble boxes faster with better consistency and a higher quality product, the company also says they have received superb support from Wayne.

In addition to being able to assemble boxes faster with better consistency and a higher quality product, the company also says they have received superb support from Wayne.

Wayne Automation followed up with this client, and is currently adding on to their machinery for further improvements. They say that process has been easy as well.

The company also noted that in addition to having more reliable equipment, all of the service technicians they have worked with from Wayne have been incredibly responsive and supportive in helping the company adjust to using the newer machinery.

Learn More About Tray Formers with Wayne Automation

Tray formers from Wayne Automation make it simple to assemble boxes of various sizes at an even higher speed than our competitor’s machines. Whatever challenges you are facing with your current machinery, Wayne Automation can help you come up with a solution. Contact us today to learn more about our tray formers and speak with our team.