Emulate3D is the leading provider of virtual commissioning software for the automation industry. This technology helps save time and money for system commissioning, which is why Wayne Automation chooses to utilize this valuable tool. Built by Rockwell Automation, Emulate3D technology supports digital twin development, facilitates controls simulation, and provides our engineering team with a unique capability to fully model our equipment designs in a physics-based environment.

“Emulate3D gives us a platform to demonstrate to our customers and integration partners Wayne equipment operating to the requirements in the early stages of a project retiring execution risk” says Wayne Automation Vice President & General Manager Jay Bachman. “This is one more way Wayne Automation works to innovate our equipment and provide performance and reliability to our customers.”

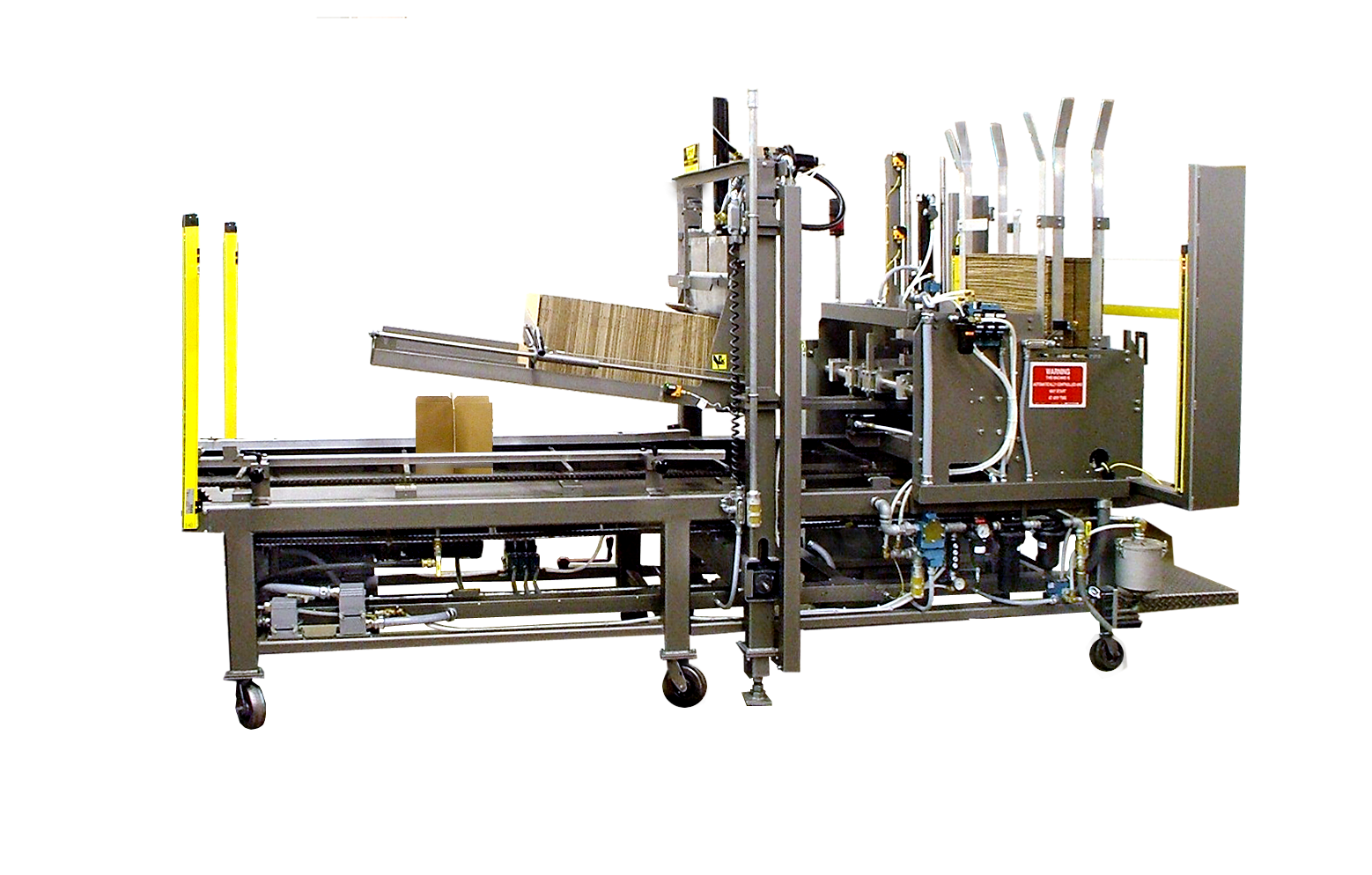

Emulate3D is also changing how transactions are done. Whereas the traditional way to purchase a piece of packaging equipment was by looking at a photo, Emulate3D allows our customers to virtually see the equipment they want to purchase, and watch it actually run in a virtual environment. With it, we can better showcase our products and our partners can find an extra level of comfort in making their purchasing decisions.

How Does Emulate3D Work?

The key to producing better automation outcomes in regards to reliability, flexibility, performance, and safety is technology. Emulate3D provides statistical backing to equipment and dimensioning choices. The digital twin aspect of the Emulate3D technology allows us to see the system or equipment virtually without ever building the physical parts. By doing this, the technology lets us detect issues and problem-solve early on.

When you first see or read about Emulate3D you might think that it’s a neat three-dimensional version of a piece of packaging machinery. But once you start diving in and peeling back the layers, it tells a very powerful story. For us and our customers, Emulate3D provides shared benefits.

How Emulate3D’s Virtual Reality Benefits Us and Our Partners

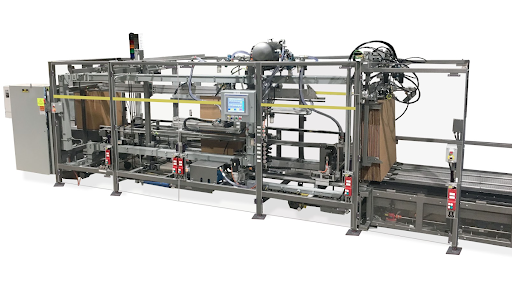

By using Emulate3D we are also able to complete our controls testing validation ahead of production. Validating the synthesis of mechanical design and controls testing in a fully digital environment allows us to provide our equipment solutions in less time, and at less cost to our partners. Using this technology also protects our partners, as we can reduce the risks of any automation investments by taking control testing off the project’s critical path. The system can be debugged more cost-effectively and safely, resulting in on-time and under budget solution delivery.

Operator training is also a big reason why Emulate3D is such a valuable tool for us and our partners. When we set up a packaging system inside of the virtual reality environment, operators can train on the equipment and even interact with packages moving on the system.

Emulate3D is extra effective for companies like Wayne Automation since we do our packaging equipment production in-house and are constantly making new, exciting machinery. Emulate3D helps us to be more efficient in the time it takes for us to design, build, and test our packaging machinery. When we can be more efficient, it translates to shorter lead times for our customers.

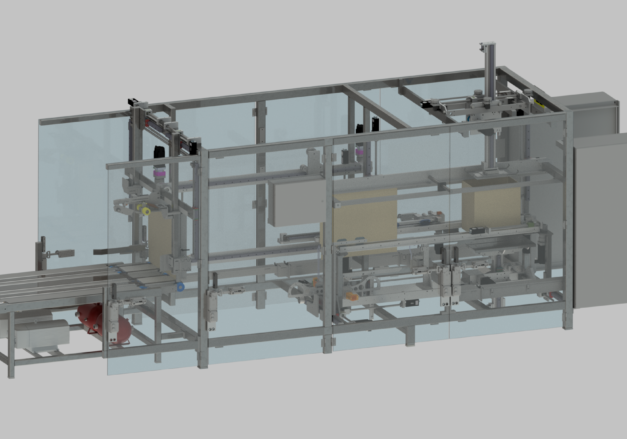

See Emulate3D using Wayne Automation CAD

Why Wayne Should Be Your Partner in Automation

When you choose Wayne Automation as your packaging automation provider, you can take comfort in knowing that we pride ourselves on using the best and most advanced technology in the development of our products. By doing so, we are able to provide exceptional products to our customers in the time and at the cost they need.

Let’s talk about your packaging automaton needs! Contact us today to learn how the Wayne approach will transform your end-of-line process.