Over the past year, we’ve all seen a massive increase in the demand for cardboard-based packaging products, both from a rise in E-commerce’s share of the market and a heavier use of packaging services as consumers shopped online due to Covid-19. Now cardboard prices are skyrocketing and with a more ecologically-minded industry base, there’s a greater focus on identifying environmentally friendly packaging materials, both to help weather the storm of market fluctuations and to get on the right path for a sustainable future. For all of these changes in the marketplace, we’re here to show you how Wayne Automation’s full line of cardboard box case erectors is ready to help assemble an ecological future for the packaging industry.

Over the past year, we’ve all seen a massive increase in the demand for cardboard-based packaging products, both from a rise in E-commerce’s share of the market and a heavier use of packaging services as consumers shopped online due to Covid-19. Now cardboard prices are skyrocketing and with a more ecologically-minded industry base, there’s a greater focus on identifying environmentally friendly packaging materials, both to help weather the storm of market fluctuations and to get on the right path for a sustainable future. For all of these changes in the marketplace, we’re here to show you how Wayne Automation’s full line of cardboard box case erectors is ready to help assemble an ecological future for the packaging industry.

Traditional cardboard is derived from 42 pound kraft linerboard, and forms the basis for the vast majority of Regular Slotted Container (RSC) style boxes we interact with on a daily basis. Per the Wall Street Journal (WSJ), demand for cardboard rose 3.4% year-over-year, totaling 407 billion square feet of corrugated cardboard product. Combine this with the vast increase in online shopping which arose due to Covid-19 lockdowns and the already rising prices of lumber, and the cardboard market underwent a commensurate rise; almost 9% growth in March over the previous year, per the Philadelphia Inquirer . The WSJ quotes consumers of cardboard packaging as paying 22% more than in previous years, and such a rapid cost inflation has begun prompting a new view on packaging options.

Already the market had been seriously considering the viability of eco-friendly materials for environmental reasons, but the past year demonstrated an economic justification as well, given the immense demand for raw materials. Recycled cardboard alternatives provide a new source of packaging material independent of the existing supply chains, and oftentimes at an economical price, too.

Already the market had been seriously considering the viability of eco-friendly materials for environmental reasons, but the past year demonstrated an economic justification as well, given the immense demand for raw materials. Recycled cardboard alternatives provide a new source of packaging material independent of the existing supply chains, and oftentimes at an economical price, too.

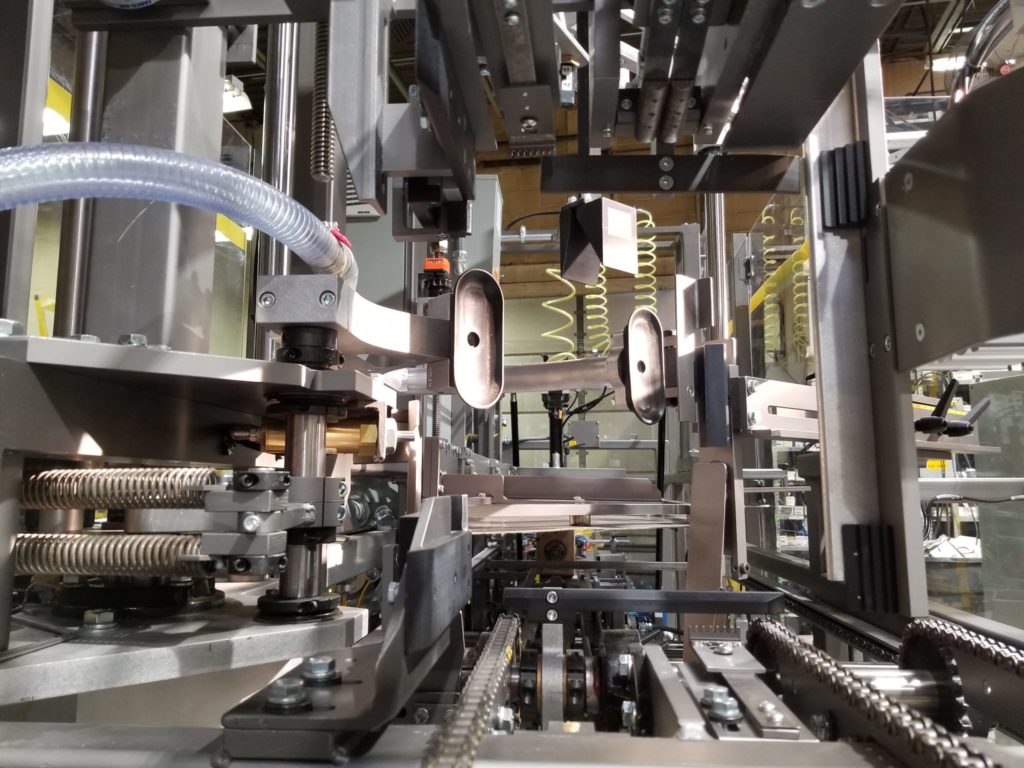

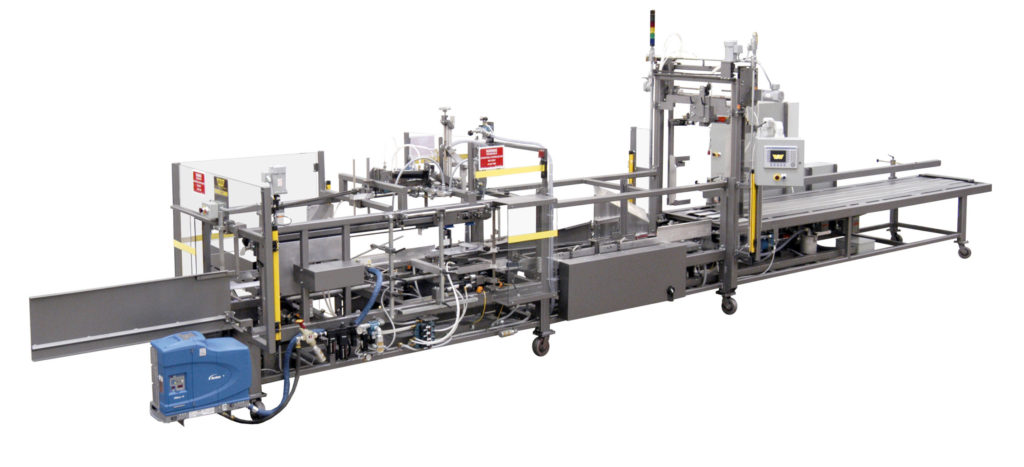

Whether the future of your industry is in traditional kraft corrugated cardboard or a newer alternative, be it recycled or otherwise, Wayne Automation has the cardboard box case erectors to meet your needs. Our case erectors are widely considered among the most reliable on the market. Designed for 24/7 production and shipping facilities, we strive to maximize speed, productivity, and safety across our entire product line.

For fully automated changeover, say for a production line which might alternate between traditional corrugated cardboard and high recycled content depending on customer, the WLRV-CE Case Erector is designed for fully automated changeover, and stands as the only case erector on the market which can handle every size between 6” x 6” x 4” up through 24.5” x 20” x 18”.

You shouldn’t need to be worried about the change to environmentally friendly options affecting your packaging automation throughput, and Wayne Automation offers a high speed option to meet this need. The VCE Case Erector has a speed of 75 Cases Per Minute (CPM) and ensures reliably formed boxes through internal and external compression mandrels, meaning one less thing to worry about when considering alternative options to newly manufactured cardboard.

We’re proud to offer case erectors for every other combination of needs, including compact footprint and servo enhanced versatility, and this extends to specialty applications too. Eco friendly and biodegradable materials are becoming more common in niche packaging, and we have multiple models of case erectors for specialty use cases, the CE-24/30 Case Erector for jumbo cases with interlocking bottoms, and a full line of Tablock Case Erectors too.

We’re proud to offer case erectors for every other combination of needs, including compact footprint and servo enhanced versatility, and this extends to specialty applications too. Eco friendly and biodegradable materials are becoming more common in niche packaging, and we have multiple models of case erectors for specialty use cases, the CE-24/30 Case Erector for jumbo cases with interlocking bottoms, and a full line of Tablock Case Erectors too.

If you want to get a head start on the competition and begin the changeover to eco-friendly materials, or just see the value in our top-of-the-line cardboard box case erectors, contact us so we can see what Wayne Automation can offer your business!