// Beverage Packaging

Sierra Nevada Gets A Case Sealer And A Partner

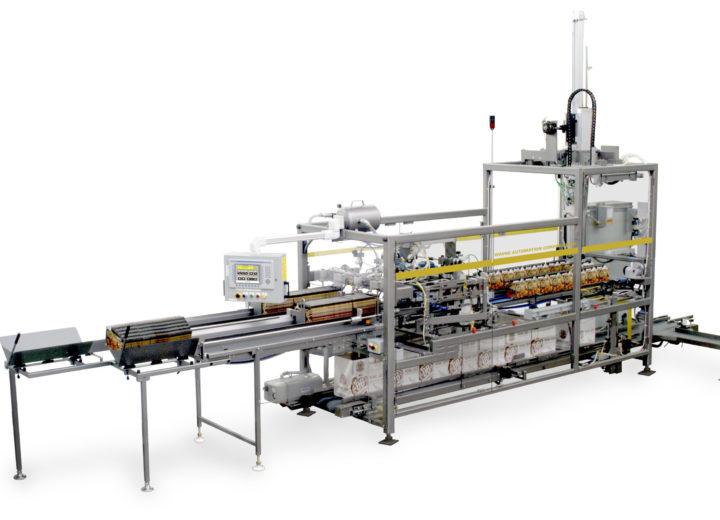

When Sierra Nevada Brewing needed to rapidly assemble uneven cases, but couldn’t risk excessive downtime or redundant machines, they relied on Wayne Automation’s reputation for unmatched quality and dedicated service.

Challenge

Sierra Nevada Brewing needed an efficient and rugged system to facilitate shipping out of their Mills River location.

Solution

Wayne Automation supplied a case erector and sealer, basing the setup off Wayne’s work at their sister brewery in Chico, CA.

Many industries use bottle packaging equipment to automate their packaging process and increase ROI.

Many industries use bottle packaging equipment to automate their packaging process and increase ROI. Case and tray packers. Our

Case and tray packers. Our